A pocket knife is a simple tool, but it is also an indispensable tool. Some folks buy pocket knives to collect, others for everyday cutting tasks, others buy them as part of their everyday carry (EDC) personal protection rig. If you are looking to purchase a new knife or want a replacement, you’re in luck; there’s a knife made somewhere to fill your needs or wants.

Purpose

The first step to a buying a new knife is to determine what you need the knife to do, and where are you more likely to use it. A useful pocket knife is not too heavy, easy to carry, and easy to conceal. Thinking of how you normally use a knife and under what conditions will help narrow down your needs.

Are you opening boxes at work? Or needing a knife to go fishing or camping? Pocket knives are not intended to baton wood—which is the practice of using a baton-sized stick to strike a blade down into a log or branch in order to cut it. That’s more of a fixed-blade chore, if you have no other means to cut wood. Shaving a stick to start a fire is different, as that’s a perfect job for a pocket knife.

Blade design

After figuring out what the knife is intended for, time to consider blade design. A clip point is still commonly used for traditional knife designs. The drop point, which has the larger belly of a skinning blade, has become a popular shape for the newer designs. There are several variations of the drop point. The basic form is a downward slope toward the tip; a clip point tends to sweep upward toward the tip.

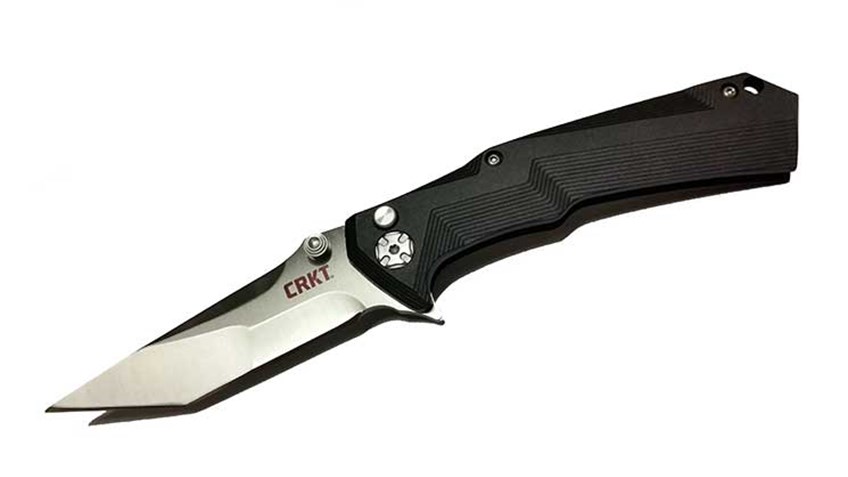

Tanto designs go back to the blades of feudal Japan. Tanto blades (as shown below) are gaining popularity in modern knife designs intended for heavy-duty use and personal defense. The two grinds of a tanto blade make for a strong tip, an excellent choice for piercing and slicing. The angle formed at the junction of the two grinds is an effective point so to speak to open boxes secured with shipping tape. One drawback of the tanto is sharpening, since you’ll have two edges to sharpen instead of one.

Depicted: CRKT Tighe Tac Two Tanto Knife.

The locking mechanism is a safety feature to keep the knife from closing when in use. The traditional pocket knife our grandfathers carried had a slip-joint mechanism, not a lock. There are three main locking mechanism designs to choose from. First is the liner lock; this may be the most common. A section of the liner springs out when the knife is opened, falling into place behind the blade, to prevent the blade from rotating back toward the handle.

Second is the frame lock that works on the same principle, except a strip of the frame blocks the blade movement. The frame lock design is considered stronger than the liner lock, due to being a thicker, heavier piece of material.

Third is the lock back design, built within the knife back or on top of it. Most consider the lock back the strongest design. One drawback is needing two hands to close the knife, unlike liner and frame locks, which close with your thumb. Another consideration is shape. A lock back generally operates an internal lock and grooves in the back of the handle for release; it is as streamlined as a liner lock and a frame lock, but some of the most aggressive lock backs require additional metal on the back of the knife.

Opening

Traditional nail nick blades need two hands to open. The modern knife opens with one hand. The opening mechanism can be a thumb stud, a hole, a disc or a flipper, made from an extension of the blade. The opening mechanism, like the locking mechanism, is something to think about and try, before buying. It will help narrow your choices.

Material

Handle material is straightforward if you want performance. You want something that feels good in the hand, material that offers traction in your grip to maintain control. Appearances have also become an important feature of handle material.

Blade steel is an argument waiting to happen. Much of the cost of the standard knife is the steel used to make the blade. Cerakote finish and bearings in the hinge are recent trends in pocket knives, but you do not necessarily need the most expensive steel in a Cerakote finished blade and bearings in the hinge to have a high-quality knife that can last a lifetime.

Granted, the more expensive steel holds an edge longer, but once you wear out the factory edge, it will take no small amount of effort to bring high-quality steel back to its factory sharpness. Major manufacturers use decent quality steel in their standard line of knives, and standard steel blades are easier to maintain.

Purchase

You want to start with a “user” knife, not one so expensive you won’t carry it or use it for the intended purpose. You can always upgrade to a higher grade knife when you want or need to. What buyers may not realize is a knife with a standard-grade blade often has the same internal parts as the higher-grade version. When in doubt, start with the basics, what is the intended use and how often, and address those needs to search for a working knife. If you take your time choosing a knife from a reputable manufacturer, it should last a lifetime.